get to know more

get to know more

With Passion

enquire now

enquire now

Our Solution

Phenol-Formaldehyde Resin Manufacturers

Find the legacy of VESKN Industry, a top-tier manufacturer & producer of high-grade Phenol-Formaldehyde Resin, having our nerve centre or headquarters in Bhiwadi, the heart of multiple industries.

Emerging as a key player with innovative ideas, helping industries get quality resin in this era of contamination. With a team of experienced workers & chemists, we as VESKN have established ourselves as one of the top-notch resin manufacturing units. We specialize in Phenol-Formaldehyde Resin production to deliver superior quality & meet diverse global industrial demands.

Emerging as a key player with innovative ideas, helping industries get quality resin in this era of contamination. With a team of experienced workers & chemists, we as VESKN have established ourselves as one of the top-notch resin manufacturing units. We specialize in Phenol-Formaldehyde Resin production to deliver superior quality & meet diverse global industrial demands.

Phenol-Formaldehyde Resin Manufacturers

Find the legacy of VESKN Industry, a top-tier manufacturer & producer of high-grade Phenol-Formaldehyde Resin, having our nerve centre or headquarters in Bhiwadi, the heart of multiple industries.

Phenol-Formaldehyde Resin Manufacturers

Find the legacy of VESKN Industry, a top-tier manufacturer & producer of high-grade Phenol-Formaldehyde Resin, having our nerve centre or headquarters in Bhiwadi, the heart of multiple industries.

Phenol Formaldehyde Resin

Novolac Resin

Resol Resin

Our Product Range

As a resin manufacturing plant, VESKN Industry operates the latest production facilities with properly equipped technology. So that, we can produce a diverse range of resins, meeting the demands or requirements of various industries. Moreover, we also provide a modified version of phenol-formaldehyde resins tailored to specific client requirements. At VESKN, we prioritize excellence, quality, commitment, & innovation.

We have a Global Presence

- Nsectetur cing elit

- Suspe ndisse sagittis leo

- Entum estibulum is posuere

- If you are going to use passage

- Lorem Ipsum on the tend to repeat

VESKN Industry

VESKN Industry

Many factors make us who we are, such as we believe in adapting to the latest manufacturing & production trends. We are expanding our capabilities to provide maximum value results to the clients.

Our

Mission

Focusing on producing superior quality products with consistency by utilizing our latest equipment & machinery.

Our

Vision

We will soon thrive as a top-class leader in the field of chemicals, resin manufacturing & production.

Our

Policy

Veskn has some strict policies regarding safety measures, material & chemical quality, product testing, production, & so on.

Gallery & Infrastructure

- Plant

- Laboratory

- Production Capacity

- Storage

- Safety Measures

Industries We Serve In

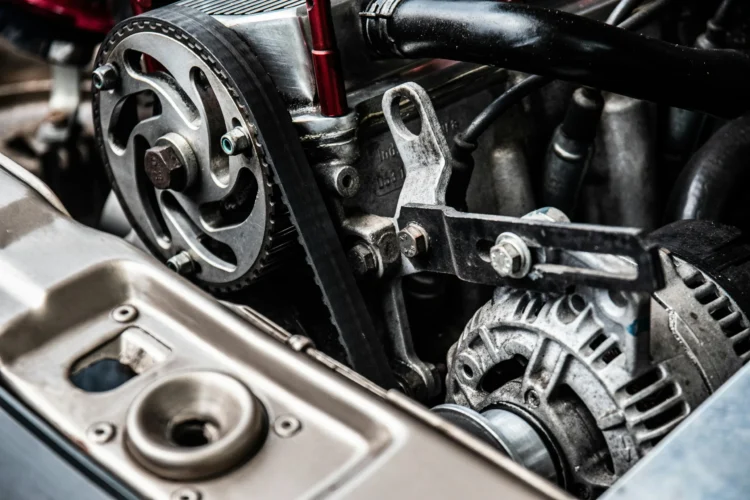

Automobile Industry

Resin plays a vital role in the automobile market. They are commonly used in adhesives, coatings, and plastic components such as bumpers, interior trims, etc. Resins also provide aesthetic appeal, durability, and weather resistance. Their excellent adhesive properties and moisture resistance make them an ideal choice for use in various devices.

Abrasives

Resins are used as the adhesion & wetting agent for the abrasive grains. They are added to the abrasive in a mixer in such a quantity that all the grains are wetted equally with a thin layer of resin as resins are used to wet the inorganic raw materials such as zircon, alumina, silicon carbide, etc.

Rubber Industry

Phenolic resins are used in rubber compounds to provide increased toughness, hardness, abrasion resistance, stiffness, & tear resistance.

Refractory

Novolacs & Resols are the most common resins applied in the refractories.

The 3-dimensional structure is essential for enhancing carbon yield & catalytic graphitization is one of the most effective methods to induce carbon crystallization.

Filtration

Resin removes chlorine & sulfur. The small resin beads are used to attract hardness-causing ions as well as to replace them with harmless sodium ions.

Mica & Wood

Mica is used in resin to give it a solid and opaque color. As mica minerals are insoluble, the numerous small particles in a mica powder pigment will retain their form when added to resin.

For this, apply a small amount of resin onto a wax surface or into a small cup & mix the mica powder into the solution, until it is completely dissolved.

Then add this to your main solution.

Looking to make a career with us!

Click on the "Join Us!" button and fill in your details. We'll contact you soon after the details are submitted via email.

Our Clients